Six Good 3D Printing Troubleshooting Guides « Fabbaloo

The good news is that most 3D printing problems have simple fixes, and you don't need to go back to school or buy a new printer. This article runs through seven common 3D printing problems with solutions to help you get a handle on your 3D printing. Let's jump in! 1. Under and over extrusion Credit. Under extrusion happens when the 3D.

Troubleshooting Guide to 7 Common 3D Printing Problems, our solution. Geeetech

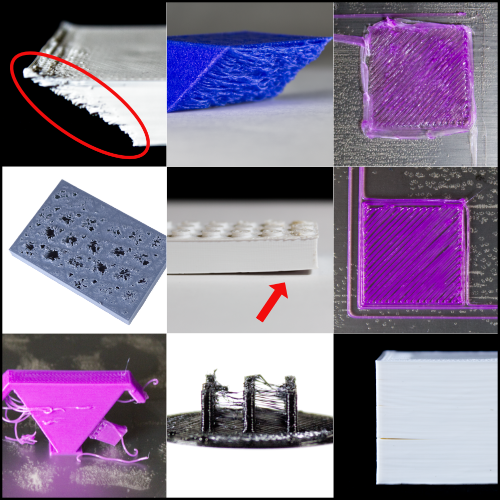

1. First Layer Adhesion Problem. Above: First layer adhesion problems in 3D Printing/Image Credit: RepRap. This problem refers to a condition where the first layer of the print does not stick to the bed. This is one of the most common problems in 3D printing encountered by 3D printer users.

Quick 5 Tips to Fix Most Common Failed 3d Printing

Causes for clogging. Unclog the nozzle with acupuncture needles. Hot and cold pulling. Teflon switching. Adjusting the printing parameters. If you don't know how to fix it, dissasemble the extruder and hotend. 👋 That's it for the 3D printing troubleshooting guide by Bitfab.

3D Print Quality Troubleshooting Hydra Research

4. Layer Separation or Weak Prints. Layer separation, or delamination, occurs when the layers of a print do not adhere properly to each other, resulting in gaps or cracks in the print. A 3D printer is essentially a hot melt glue gun controlled by a robot. And hot melt glue works because it is, well, hot.

3D Printing Most common problems for beginners Ram Peripherals 3D Printing & Disc

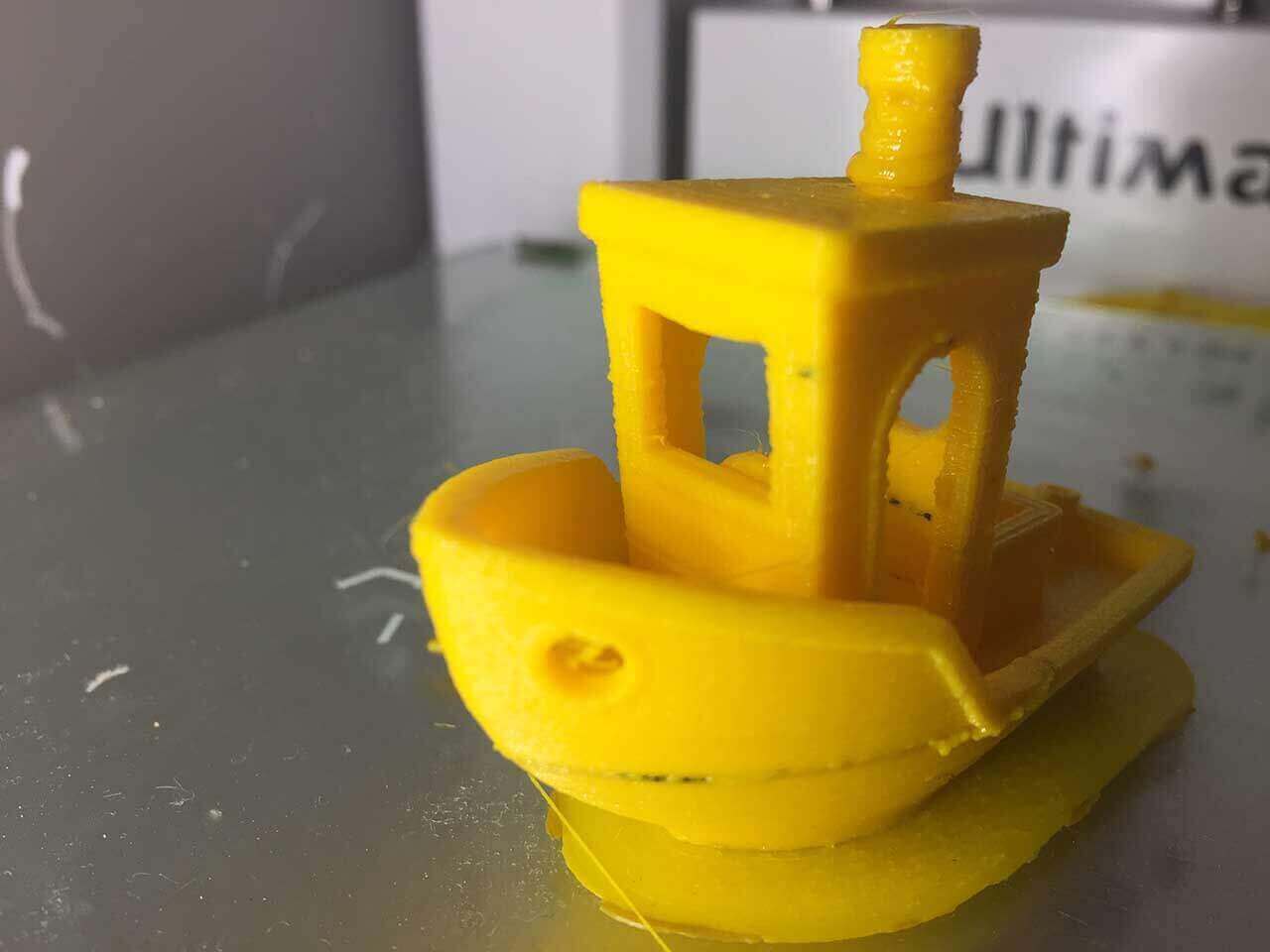

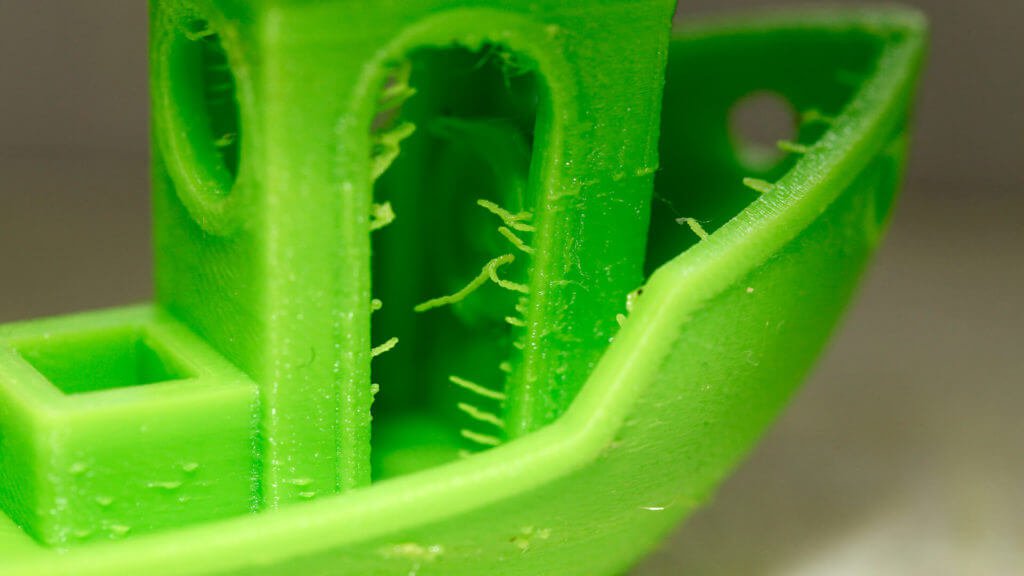

3D printing has come a long way in terms of technology and capabilities, but it still poses challenges for some users. From over-extrusion to stringing and surface imperfections, the most common problems encountered while 3D printing are usually quick fixes with the right knowledge and understanding. By understanding and addressing these.

Troubleshooting Guide to 19 Common 3D Printing ProblemsPart One Geeetech Blog

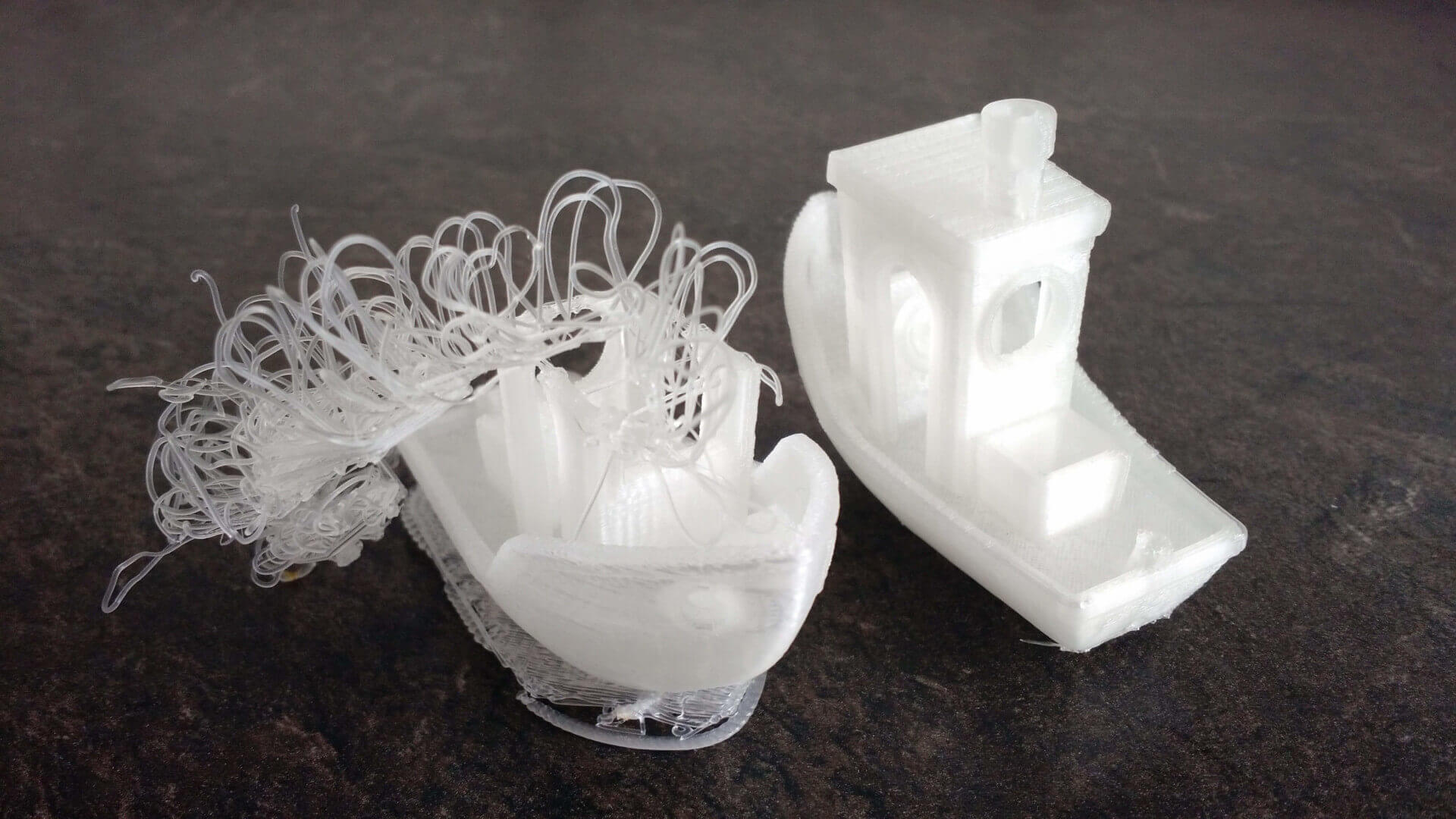

Insufficient cooling: Check that the fan turns on after the first couple of layers, and make sure that it is pointed directly at the print. Minimum time per layer too low: Go to settings -> advanced and find "Min time per layer". Increase this number. 10. Printing in the air.

Simplify3D Releases Comprehensive Troubleshooting Guide for All Your 3D Printing Issues

Most Common 3D Printing Errors. Either you are a beginner or an experienced 3D Printing user, getting trapped in between a print is not something rare. We all go through such problems when 3D printing. Sometimes our prints won't stick to the surface and other times, it may start oozing. These do seem scary.

Troubleshooting Guide to 24 Common 3D Printing Problems Part 1 Geeetech

3D Printing is by far the largest community with over 240.000 members. Well-known experts such as Josef Prusa, Thomas Sanladerer, Nils Hitze, Brook Drumm and many others hang out here. Within the community there is a sub-section called Questions/Help, the go-to place for 3D printing problems and solutions:

5 Common Problems Faced with Metal 3D printing And How You Can Fix Them FacFox Docs

This would end in a blockage. In this 3D printing issue, raising the height of the nozzle is the simplest solution. Most of the 3D printers would allow you to do this in their system settings, by Z-axis offsetting. You will have to increase the offset value by keeping on adding more to the present value.

Troubleshooting Guide to 19 Common 3D Printing ProblemsPart One Geeetech

3D Printer Troubleshooting: Pillowing. Filament size. More common with 1.75 mm filament. Pillowing is an issue that can affect all 3D printers, however, it's far more common on those using 1.75 mm filament over 2.85mm. Check the fan position. Cooling is normally the issue start by checking your fans.

Troubleshooting Guide to 19 Common 3D Printing ProblemsPart One Geeetech

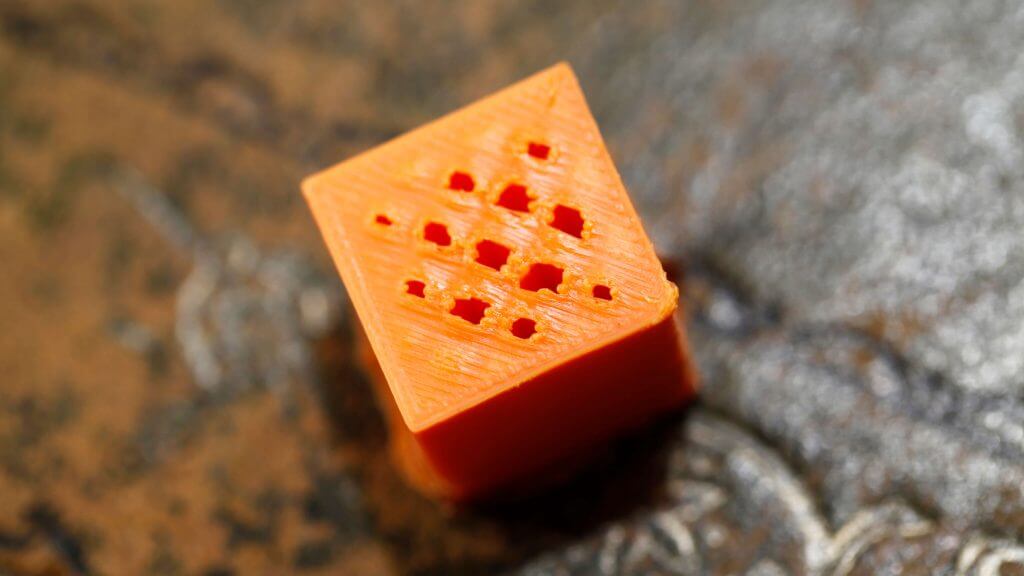

This guide outlines some of the most common issues faced by 3D printing practitioners and highlights steps that may be taken to resolve those issues. Not extruding at the start of the print. Print not sticking to bed. Jammed nozzle/clogged extruder. Pillowing, e.g. incomplete top layer fills, top layer holes/gaps.

Troubleshooting Guide to 24 Common 3D Printing Problems Part 1 Geeetech

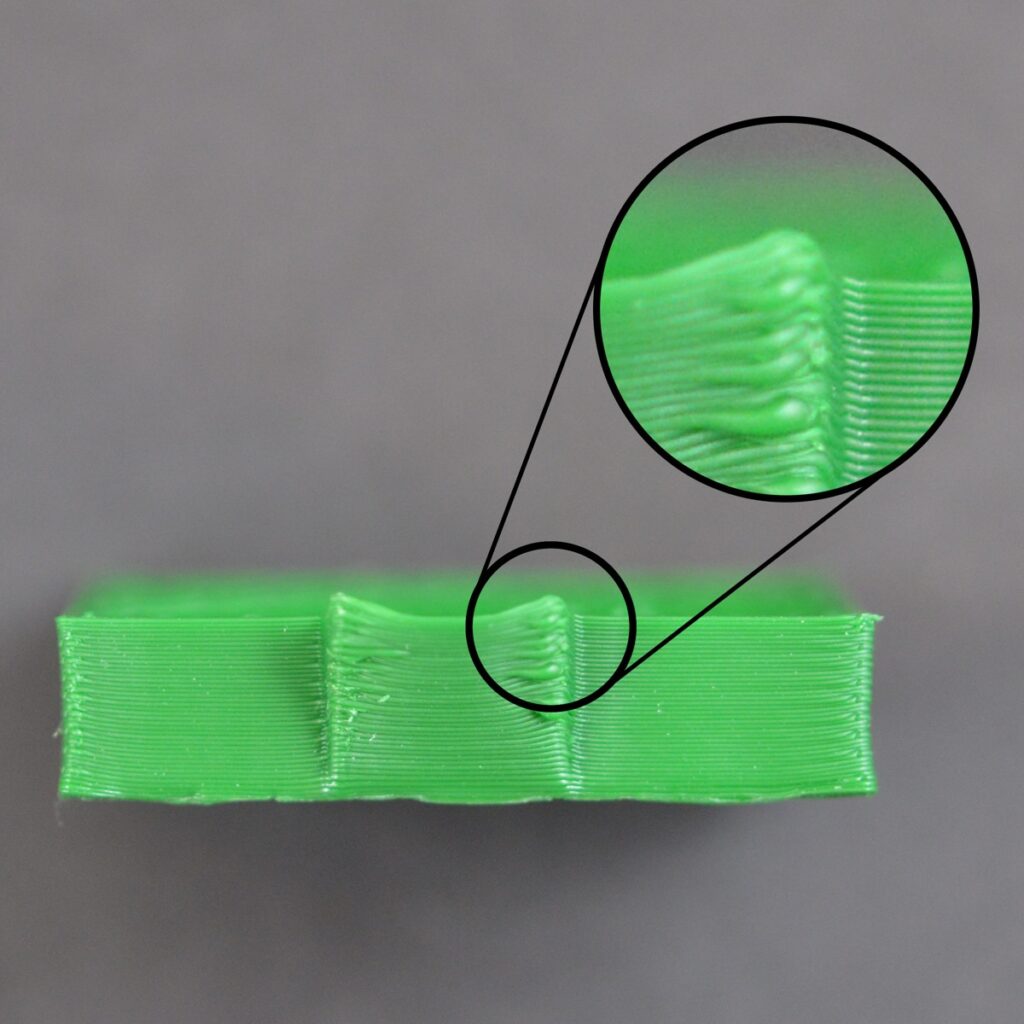

During 3D printing of the first layer, the individual lines don't touch each other. There's small gaps where the lines of the infill don't touch the outlines of the wall. The shape of the extruding line is very round. With the proper distance, the extruded line of filament is slightly squished, and pancake-shaped.

Guía de resolución de problemas de impresión 3D 3D Neworld

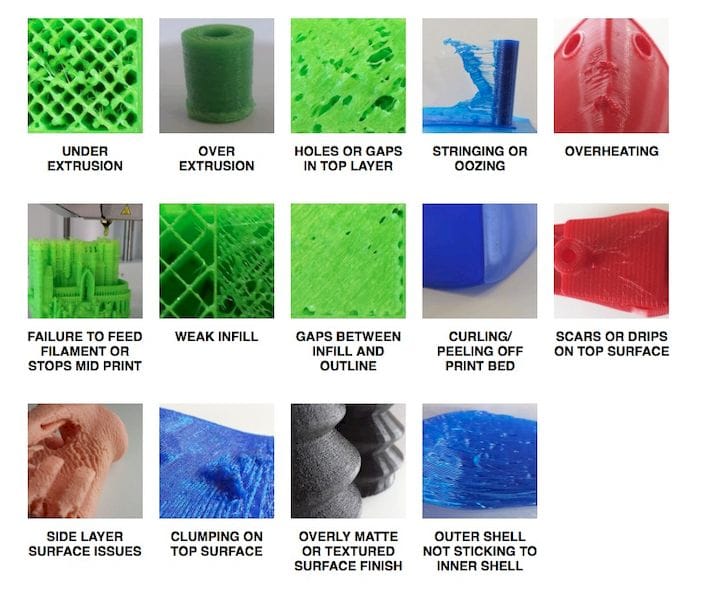

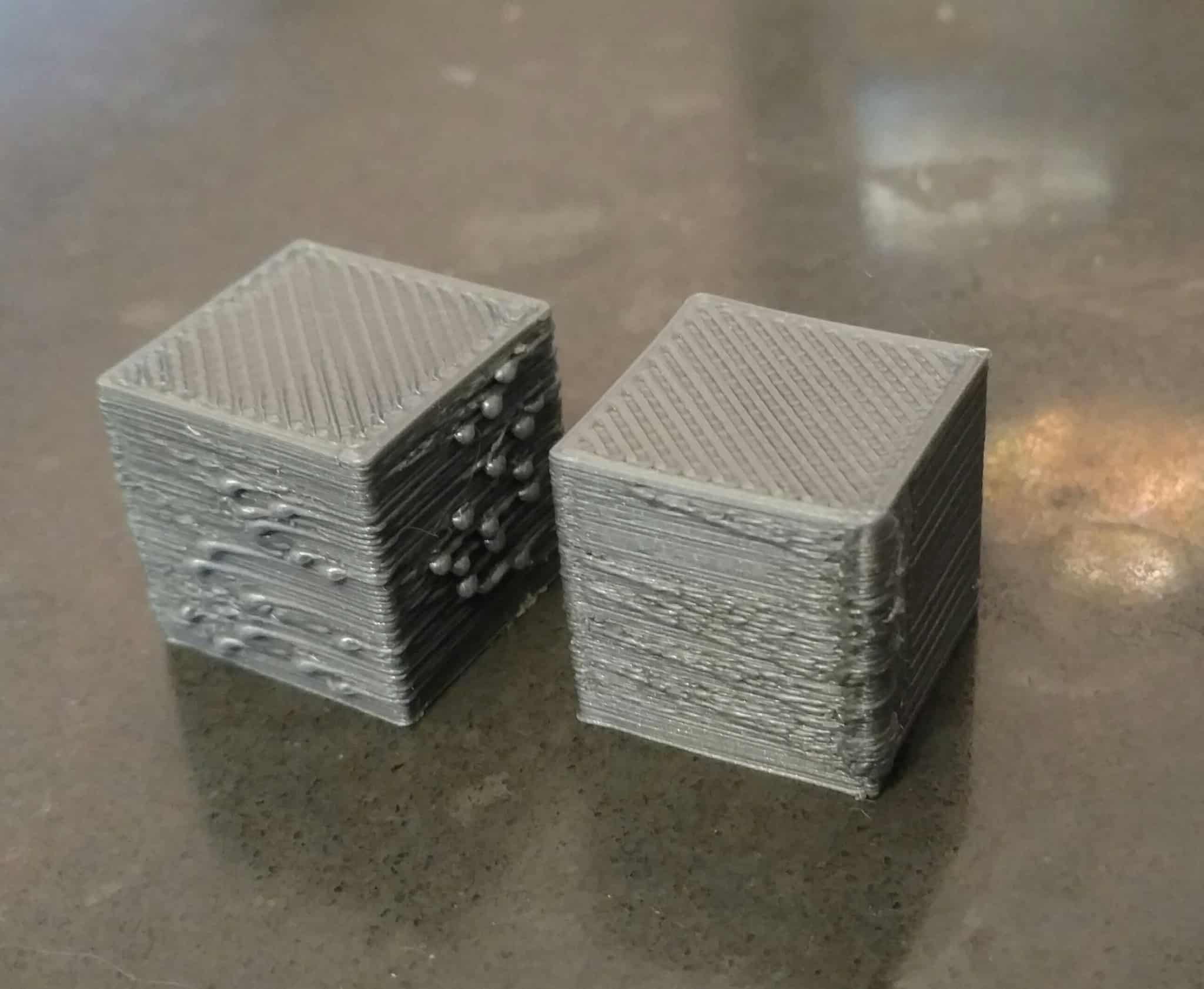

Print Quality Troubleshooting Guide. This guide is a great place to start if you are trying to improve the quality of your 3D printed parts. We have compiled an extensive list of the most common 3D printing issues along with the software settings that you can use to solve them. Best of all, the guide uses a large collection of real-world images.

Simplify3D Releases Comprehensive Troubleshooting Guide for All Your 3D Printing Issues

Post-processing: Some gaps and holes can be fixed after printing by using fillers, sandpaper, vapor polishing, or other methods to smooth out the surface and close up the gaps. Gaps and holes in 3D printing cause major problems: they're ugly to look at, ruin your model, and make useable parts unstable and even brittle.

Troubleshooting Guide to 19 Common 3D Printing ProblemsPart One Geeetech Blog

Key Takeaways. 3D printing problems: The article explains common 3D printing problems, such as poor adhesion, warping, clogging, stringing, and over-extrusion. Problem identification: Each problem has a clear photo, a description of the symptoms and causes, and a checklist of possible solutions. Problem prevention: The article also provides.

Troubleshooting Guide to 7 Common 3D Printing Problems, our solution. Geeetech

Heated print beds solve a lot of problems in 3D printing, but they cause some problems, too. One such issue is called elephant footing, where the first few layers become "squished", flaring out wider than intended. Large and heavy models are most at risk, as the weight of the model pushes down on the base of not-quite-solid filament..